Premedia & Printer Requirements | Printing Files with Digimarc Barcode

Digimarc Barcode is an advanced barcode that is implemented by applying a patterned graphic treatment to individual color separations in the artwork. This contrasting pattern carries product data, which can be scanned by enabled barcode scanners and smartphones. Digimarc Barcode is applied to print-ready, color-separated art files and is optimized for performance based on the printer specifications provided by the printer to the Digimarc enhancement partner. If you are unsure of the provided print specifications reach out to your enhancing partner.

Watch the Printer Quality Control video series to gain a deeper understanding of how to use Digimarc tools to perform the required quality control checks and data validation when printing jobs with Digimarc Barcode.

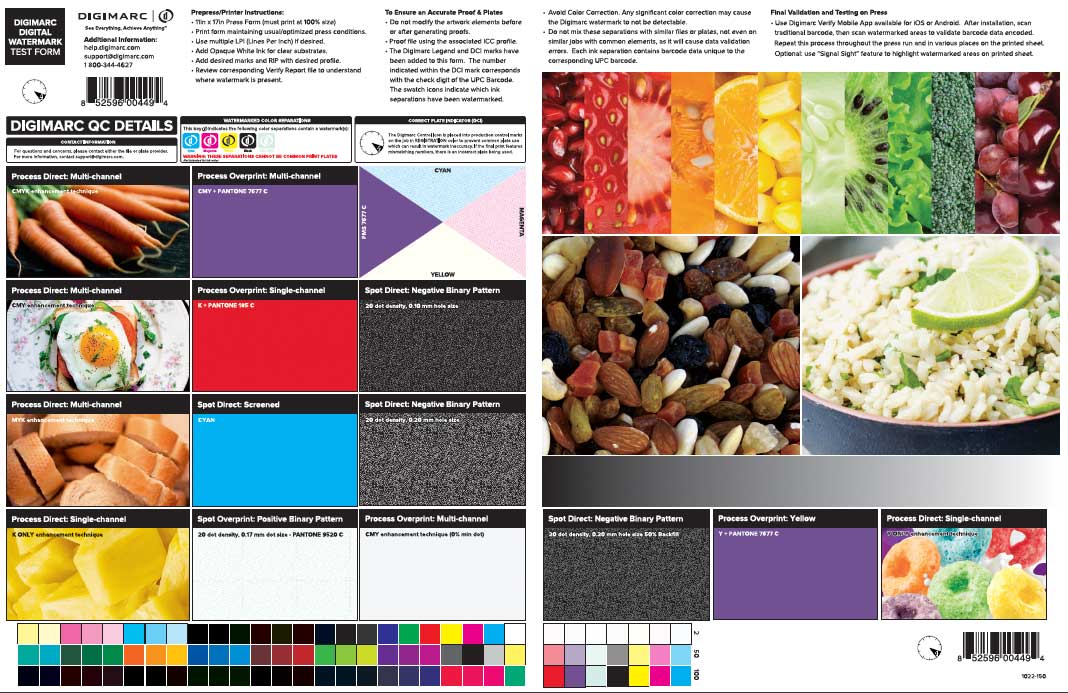

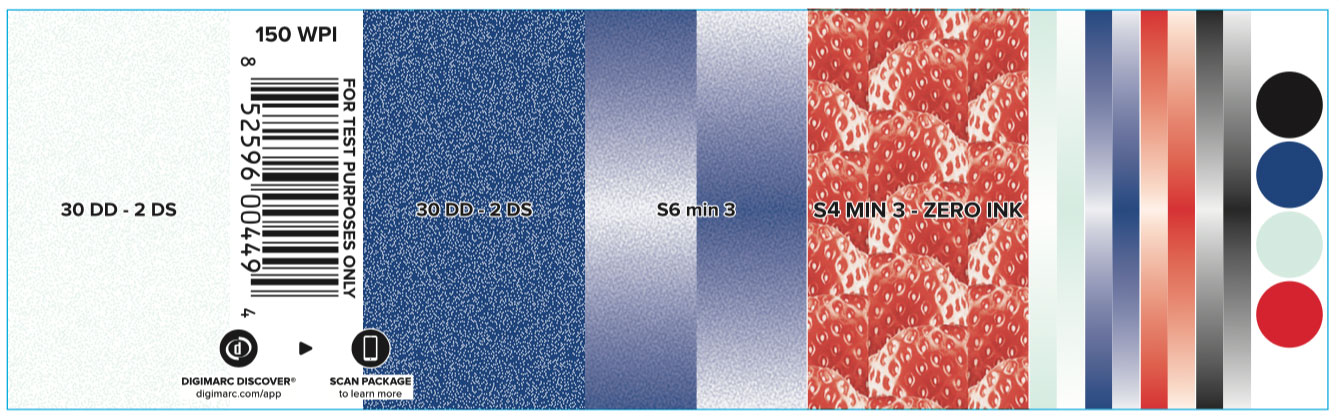

Download the Digimarc Barcode Test Press Sheet to get familiar with Enhancement techniques and to test Digimarc QC Tools.

Download the Digimarc Barcode Dry Offset Test Art

NOTICE: Files with Digimarc Barcode contain a unique code embedded in design elements in each enhanced separation. Linking to common enhanced design elements or leveraging common printing plates between similar package designs will result in multiple product codes on a single package and errors when scanned.

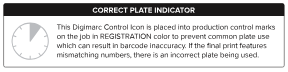

Digimarc provides a Digimarc Control Icon that is placed in the control marks of the artwork and used to visually confirm there is not a mismatch. Refer to the Digimarc Control Icon guide for further information.

CRITICAL ATTENTION FOR PRINT OPERATIONS

Any of these items that are not followed may cause scanning issues and may require reprinting.

- Color Corrections

Do not perform any color corrections or image scaling on enhanced files, and do not reuse any enhanced design elements across multiple SKUs. - Printer Specifications

Digimarc Barcode relies on the printer's provided specifications for the intended press environment. Production printing that falls outside of the provided specifications risks performance errors in end-user scanning. - Solid Ink Colors

Digimarc Barcode performance will be impacted if solid ink color and/or density deviate more than 4∆E or 2.8 ∆E2000 change from the press color profile provided. - Tone Value Increase

Tone Value Increase (TVI), or "Dot Gain", shall be kept within 4% for the printed 50 percent tone target supplied in the .icc profile. As a default, Digimarc refers to ISO 12647-2 Curve B with a 50% printing to a 69% (Murray-Davies). The maximum tone value shall be kept ≤99% as specified in the .icc profile. As a default Digimarc refers to 95% = ≤99% for process colors and 90% = ≤99% for spot colors. For questions on utilized print specifications please contact the premedia provider for more information. - Visual Appearance

When viewing separations at magnification, you may notice what appears to be pixelation in otherwise smooth areas – this is the Digimarc Barcode and shall not be altered. Printing outside of specifications can significantly increase the visibility of Digimarc Barcode and cause failure on print-to-proof color reproduction.

NOTICE: Printed areas of spot color that include Digimarc Barcode will appear to have a color change; please defer to the proof for visual appearance and refer to the control strip for measurement.

Additional Considerations

Packages with large areas of white ink, transparency or exposed substrate may require special treatments. Digimarc Barcode can be applied with a specially formulated spot varnish to encode these unique scenarios. Contact your file provider or Digimarc via our form at http://www.digimarc.com/help for more information.

Quality Checks For Digimarc Barcode

- Color consistency: Final print that is outside 4∆E2000 to the provided ICC profile or CXF spot color standards may cause retail scan failures. Digimarc references the GRACoL 2006 ICC profile and Pantone Coated color targets when no ICC profile or custom color standards are provided.

- Data accuracy: Digimarc Verify – Mobile app (iOS and Android) is used to QC print samples for GTIN alignment between UPC code and Digimarc Barcode and to check multiple print areas.

- If any press environment changes are required, contact the file provider to determine if the modification will adversely affect Digimarc Barcode.